Racking Multi-Directional Shuttles: The Future of Warehouse Efficiency in New Zealand

- BOP Racking

- Sep 5, 2025

- 2 min read

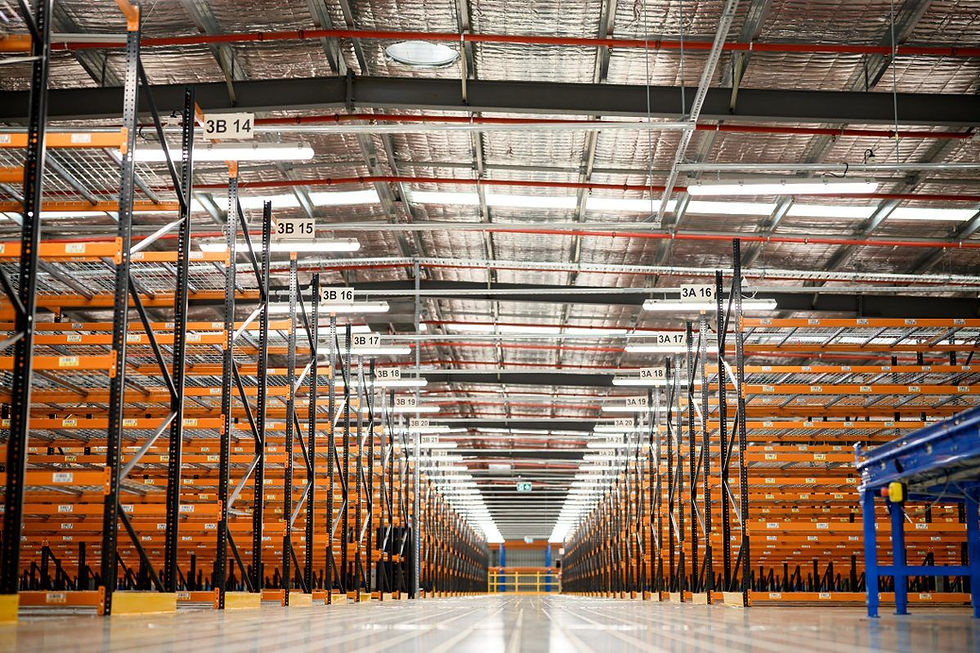

In the fast-paced world of warehousing and logistics, efficiency is everything. As Kiwi businesses look for smarter ways to store, access, and distribute stock, multi-directional racking shuttles are emerging as a game-changer. For companies across New Zealand—whether in manufacturing, retail, or third-party logistics—this technology offers an innovative approach to maximising space and streamlining operations.

What Are Multi-Directional Racking Shuttles?

A multi-directional racking shuttle is a semi-automated storage system designed to move pallets within racking without the need for forklifts to enter the aisles. Unlike traditional pallet racking or single-direction shuttle systems, these advanced shuttles can travel both longitudinally and laterally within the racking structure.

This flexibility allows:

Dynamic pallet movement in multiple directions.

Greater efficiency in loading and unloading.

Reduced forklift travel distances and labour costs.

Better space utilisation in high-density warehouses.

Key Benefits for New Zealand Warehouses

Maximise Storage Capacity

With multi-directional shuttles, businesses can achieve higher storage density, making them perfect for warehouses where floor space is at a premium. This is especially valuable in New Zealand, where land costs are rising in urban centres like Auckland, Wellington, and Tauranga.

Faster Throughput & Reduced Handling

By automating pallet movement within the racking, shuttles reduce reliance on forklifts, cutting down handling time and the risk of damage. This speeds up order picking and dispatch, crucial for industries like food distribution and e-commerce.

Improved Safety

Less forklift traffic in aisles means fewer chances of accidents, a vital consideration under New Zealand’s strict workplace Health & Safety regulations.

Scalable & Flexible

These systems can be tailored to suit a variety of warehouse sizes and stock types, making them suitable for both small regional warehouses and large national distribution centres.

Why Consider Multi-Directional Shuttles Now?

The New Zealand logistics sector is under increasing pressure due to labour shortages, growing online retail demand, and rising operating costs. Investing in automation and smart racking systems is no longer just an option—it’s becoming a necessity for staying competitive.

Multi-directional shuttles not only future-proof your warehouse but also provide a strong return on investment by improving throughput, reducing damage, and maximising storage density.

Bay of Plenty Racking: Your Local Racking Experts

At Bay of Plenty Racking, we specialise in providing innovative racking solutions for New Zealand businesses. From pallet racking and mezzanines to advanced shuttle systems, our team can design, supply, and install solutions that transform the way you use your warehouse space.

If you’re considering a multi-directional shuttle system or want to explore whether this technology is the right fit for your operation, talk to our experienced team today.

📞 Contact us now to arrange a consultation and see how automation can take your warehouse to the next level.

Comments