6 Ways to Maximise Your Warehouse Space

- BOP Racking

- Jan 14, 2020

- 2 min read

Updated: Jan 14, 2020

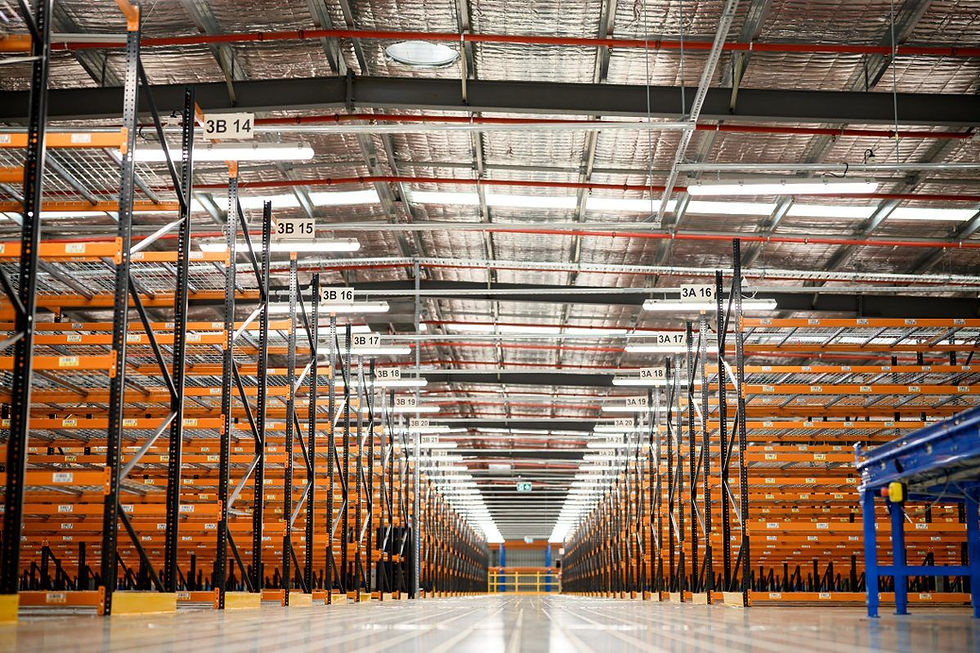

Are you finding it difficult to easily store stock? Are your staff spending expensive time looking for items? Here are some top tips on how to best utilise the space you have.

Are overwhelming stocking issues causing you grief?

Extending floor space, adding onto your current building or relocating can be extremely expensive. At Bay Of Plenty Racking we have devised five top tips to help you better utilise the space you have to avoid these expensive costs.

1. Going Higher

Whilst remaining in compliance with building codes, it may be possible to extend your racks further into the air. Often it is possible to add onto your existing racking by using splice kits. This follows the simple equation, more racking = more stock per square.

2. Binning Systems

Here at BOP Racking we offer precise, easily labeled binning systems that will help organise your warehouse! By using binning systems small parts can be easily found and accessed. This saves staff time which increases productivity and saves you money!

3. Adjusting Beam levels

It's perhaps the most common mistake that warehouses are making. When you have empty space in between stock and beams you are paying to store air! This cost can be found in almost every business. BOP Racking specialises in saving you money and by getting rid of this wasted space we help you maximise your profit and get ahead of your competition!

4. Reduce Aisle Space

Narrow Aisle Racking is becoming very popular in warehouses with hand loaded stock. Wether you have hand loaded stock or pallet sized cartons, different forklifts require different manoeuvring space. You may be losing storage space in between your racks that can be costing you in lost storage. We can help tighten this floor space to allow for extra storage whilst maintaining adequate turning space for your machinery.

5. Double Up

Double deep racking stores two pallets deep in a single entry rack or four pallets deep in a double entry rack. This system requires the use of a special reach fork lift truck with either dual pantograph or sliding fork attachments. Double deep racking improves storage density with fewer aisles and more storage locations. This reduces the aisle to rack ratio which means more stock!

6. The Best Possible Solution

Easily the best possible way to maximise your storage however is to get in touch with BOP Racking! Our experts can come to you to talk over your specific needs and give you the best possible solution. Get in touch!

Comments