Best practice for pallet racking systems

- BOP Racking

- May 18, 2023

- 2 min read

Most regions of New Zealand are prone to earthquakes, and bulk storage facilities and retail stores must consider building restraints for contents as part of their safety management programmes.

The standard for Seismic restraint of building contents (NZS 4104) requires the restraint of building contents in certain conditions.

The standard provides considerable detail, and building owners and persons conducting a business or undertaking (PCBUs) should make themselves aware of its requirements.

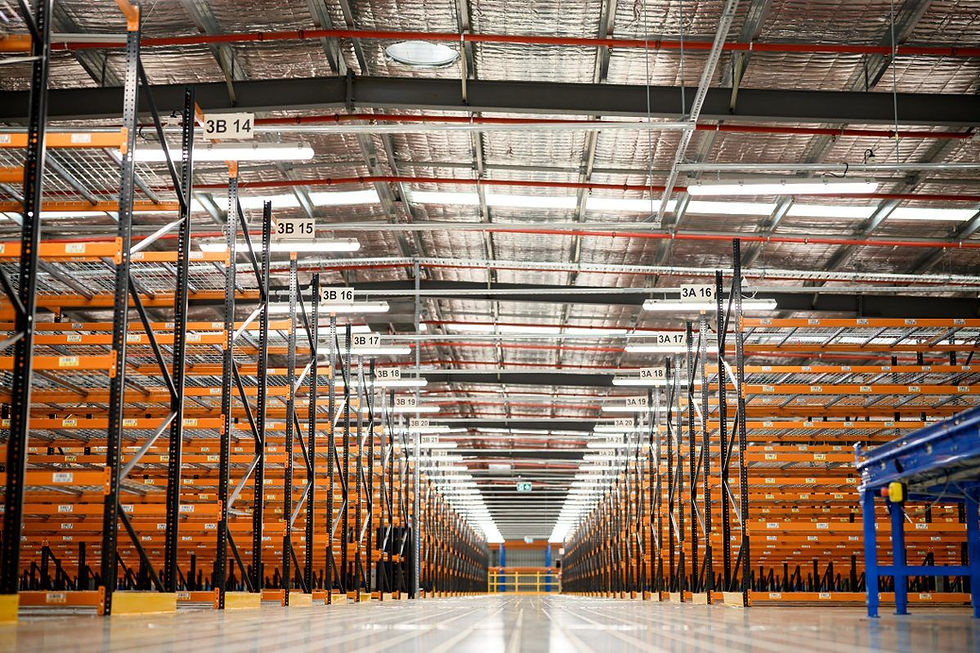

A yearly safety audit on pallet racking is considered crucially important in New Zealand, as it helps ensure the safety and integrity of the racking systems.

However, over time, wear and tear, improper use, or changes in storage needs can compromise the structural stability of the racking.

Conducting regular safety audits, including an annual audit, allows businesses to identify any potential issues or hazards with their pallet racking systems. These audits involve a comprehensive inspection of the racking components, including uprights, beams, connectors, and safety devices.

The purpose is to identify any signs of damage, such as bent or corroded parts, improper installations, or overloading, which could lead to structural failure or accidents.

New Zealand has various regulations and guidelines in place to ensure workplace safety, including those related to pallet racking. For example, the Health and Safety at Work Act 2015 places a duty on employers to provide a safe work environment, and the Approved Code of Practice for Storage and Retrieval Systems (ACoP) provides guidance on managing risks associated with pallet racking.

While there may not be a specific legal requirement mandating annual safety audits, regular inspections and audits are generally recommended to comply with workplace safety regulations and mitigate potential risks. Moreover, conducting audits annually or at appropriate intervals is considered a best practice to maintain the safety and efficiency of pallet racking systems.

It's important to note that workplace safety requirements and guidelines can change over time, so it's crucial to stay updated with the latest regulations and recommendations from relevant authorities in New Zealand. Consulting with safety professionals or regulatory bodies can provide specific guidance tailored to your industry and situation.

WorkSafe New Zealand recommends that PCBUs should engage a consulting engineer or certified racking inspector to review their shelving systems’ verification and certification to ensure that they meet the requirements of NZS 4219 – Seismic Performance of Engineering Systems in NZ buildings

Comments